How to select your wooden floor?

Choosing the perfect wooden floor is one of the most basic yet important decisions when creating a space. With so many woods, tones, patterns and grades to choose from, it can sometimes be hard to see the wood for the trees, if you’ll excuse the pun.

Please ensure you allow for sufficient wastage. Our minimum order quantity is 2m2 (or pack size) but there is a small order charge of £185 + Vat for orders <15m2.

Hopefully, the following tips will help you make up your mind. In stark contrast to the more commonly used seals and lacquers, which form a plastic-like film on the surface of the wood, our finishes maintain the natural warmth and liveliness of the material, enhancing the product’s natural beauty and durability.

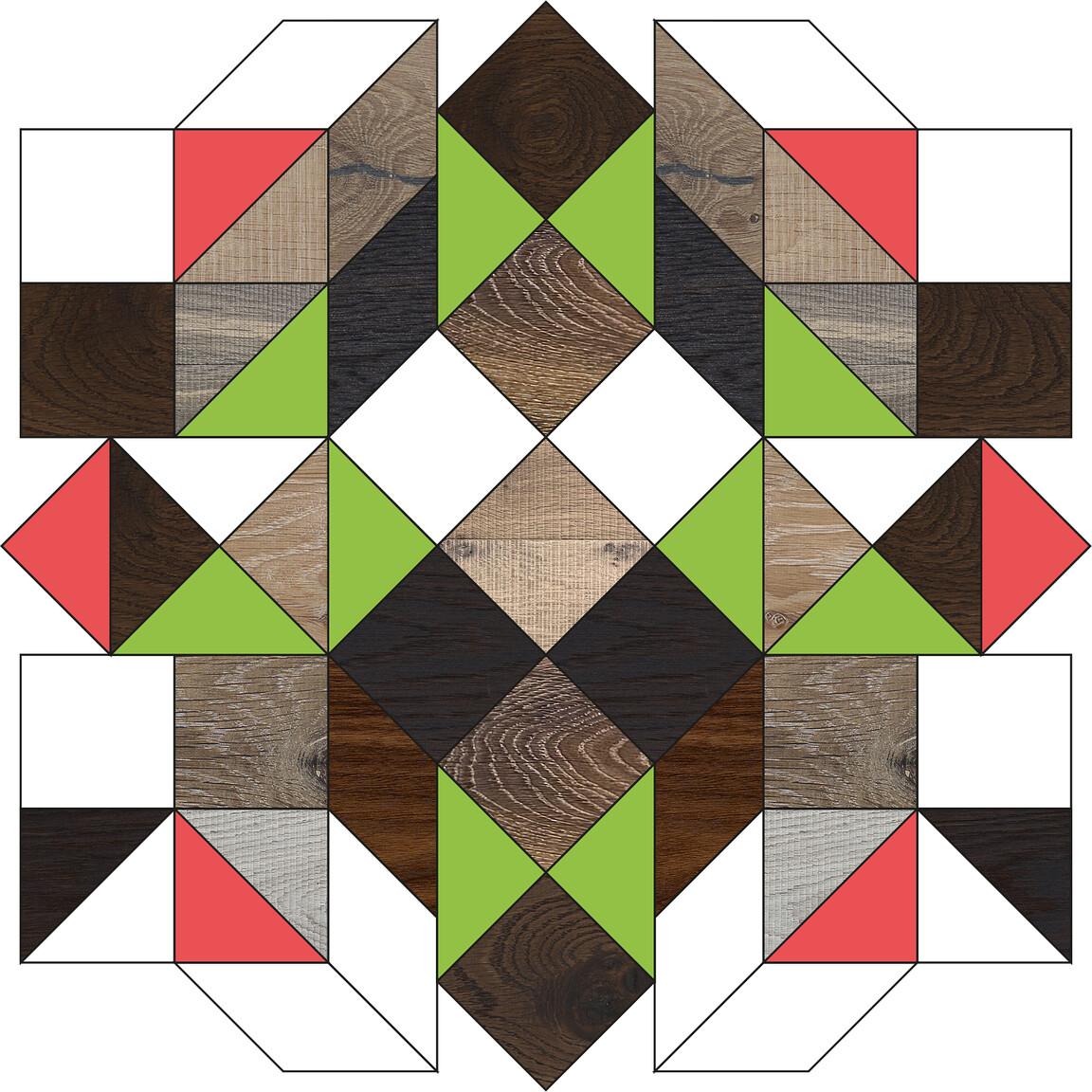

Patterns and dimensions

Once you’ve chosen your preferred colour of wood floor, you should decide on the pattern. Most of our flooring can be produced as boards, panels, and herringbone or chevron parquet. Available sizes are specified in the spec sheet which can be downloaded for all our colours.

Boards

Chevron

Boards in mixed widths

Versailles

Herringbone

4s panel

Wood grades explained

Your next choice is the grade of the wooden flooring. The wood grade simply refers to the size and number of knots and other slight imperfections that provide that rustic, aged appearance such as sapwood and natural cracks.

There is no recognised international standard for grading wood but as we only use a handful of quality European manufacturers, we are able to divide our range of oak floors into three categories - rustic, classic/ rustic A, and premier.

So while some floors look good with a few knots and imperfections to give that rustic, aged appearance other, more contemporary tones look better in a premier grade. Please refer to the technical sheet for the description of the grades and go to our project gallery to see examples of fitted floors in various grades.

Note the grading descriptions for oak don’t apply to other species like Maple, Walnut, Douglas fir and larch. Further, the grading descriptions should be seen as a guideline only due to the fact that wood floors are a natural product.

Rustic

Classic/ Rustic A

Prime or Premier

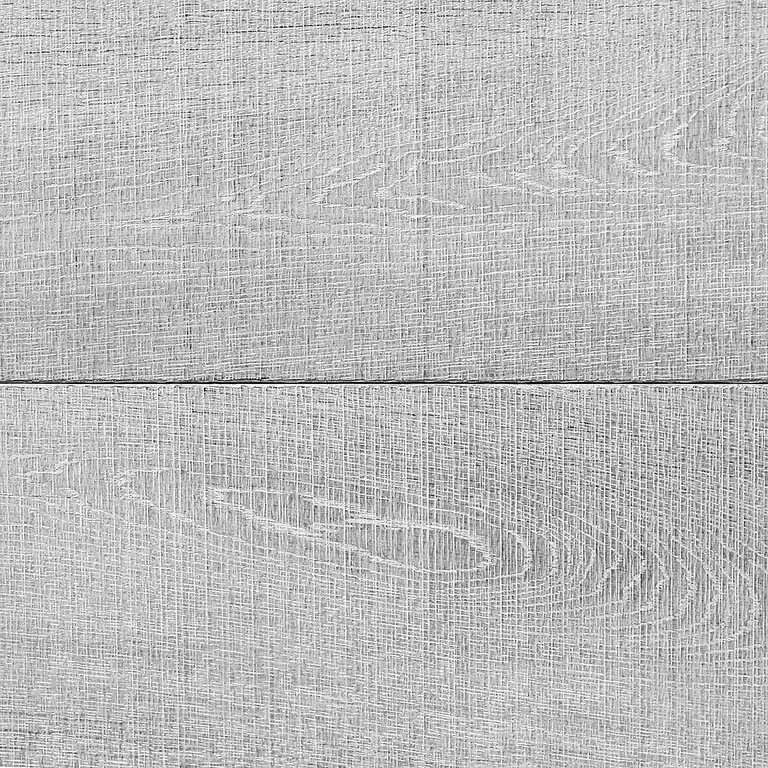

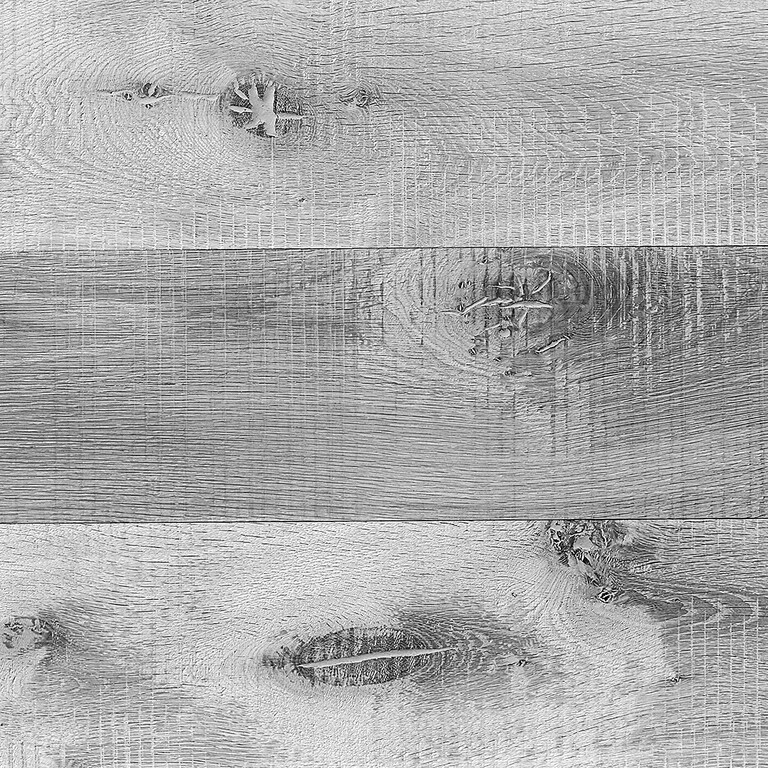

Textures

Whilst some of our floors are only available in a specific surface finish to maintain colour consistency, many of them can be produced in a range of surface finishes and textures from brushed, planed or scraped and sawn, to the distinct saw marks of our popular Treehouse range.

Although we don’t promote on-site finished floors, we do offer solid floors that need some degree of on-site finishing. However, we don’t recommend laying solid floors over underfloor heating, no matter what thickness they are.

Planed

The sharp blades from the surface planer open the pores in the oak, allowing the oil to penetrate deeper compared to a sanded surface.

This technique results in earthy colour tones and extremely durable finishes, while the subtle marks from the planer give the floor a unique aged appearance.

Brushed

Wire brushing the wood removes the soft parts of the wood and gives it a subtle textured feel, while also ensuring that surface scratches from everyday use are less noticeable.

It is the perfect finish for softer hardwoods such as Walnut and very dark colours such as Smoked oak and Smoked Oak Black.

Treehouse

Our Treehouse range is unique. The band saw gives the wood a rippled, rough sawn surface with saw marks stretching across the entire board.

Treehouse boards can be ordered with or without hand-cut bevelled edges.

Scraped & sawn

Rough marks from the scraping combined with random saw lines produce an authentic and worn-in surface or what is often referred to as a ‘reclaimed’ or ‘shabby chic’ look.

The scraped and sawn range looks its best with a hand-cut, uneven bevel to enhance the natural appearance of the wood.

Stair solutions

Most floor installations entail the cladding of a step or two, or indeed entire staircases. There are different solutions for stair profiles and depending on the type of step you want, our in-house production team can tailor noses (solid bullnose, solid square nose, and square nose) and treads from solid single-width boards, with or without curves and in a range of profiles (pencil round, rounded, or fully rounded).

Why not order a few samples from our range? Alternatively, why not visit our showroom where you can see large samples of the various grades. We’ll be happy to talk you through the various options.